| Flavors Technology Incorporated |

PIM/Paracell Application Notes |

|

The Manufacturing Agility Server (MAS) will reduce down-time in high-volume assembly operations by dynamically reassigning failed operations from one device to another. It achieves this functionality through the use of autonomous software agents. MAS functionality is not provided in current or forthcoming commercial products.

The reliability of individual devices limits the productivity of manufacturing lines. The MAS reassigns operations from failed devices to others that are still functioning. The need for MAS is illustrated by the structure and operation of a line of welding robots in an automotive body assembly shop, though the technology has far broader applicability.

A typical body assembly line (Figure 2) consists of a series of robotic cells, each containing one or more robots. Each auto body moves sequentially from cell to cell through the line. At each cell, the devices in the cell perform a series of operations. One robot fixtures a new component to the body, while others apply spot-welding guns to selected joining locations. Sometimes a panel is tacked in place at one cell, then reinforced with further welds at a subsequent one.

Operations are allocated across multiple robots to meet manufacturing capacity requirements and to maintain product sequence. A typical automotive body assembly line contains as many as 250 separate robots, many with overlapping capabilities.

Robots aren't perfect. Sometimes one of them breaks, and is unable to perform its operation. Under current control technology, the production foreman has two choices: shut down the line (losing valuable production time), or mark the body for later manual rework (leading to tardiness, and reduced uniformity and quality). As a result, a manufacturing line is stopped from 5% to 20% of the time, leading to expensive loss of productivity.

Manufacturing devices such as welding robots have extensive overlaps in capability, and there is usually excess capacity available at selected devices as well. In principle, they could reassign missed operations, but in practice the control technology to enable devices to negotiate reassignments is not available. The MAS provides this functionality.

The problem is far broader than just automotive assembly. Many industrial controls applications consist of a series of programmable devices with overlapping capabilities that manipulate product as it is manufactured, including:

- Machine tools in a machining cell or transfer line

- Material handling devices, such as automatic guided vehicles or modular conveyor segments

- Reactors, extruders, dryers in a polymer plant

- Pick-and-place robots in a printed circuit board stuffing application

This project will focus on the robotic welding application. But Flavors Technology is committed to migrating the technology to other applications over time.

Vision [Return to Top of Page]

Unlike robots, people are able to fill in for one another's operations. One worker who is unable to complete a specified operation asks for help. Coworkers reply according to their capabilities and current capacity. Sam might have the right tool and be in the right position, but be too busy; Jane might have time but not the right equipment, and Sue might have both the equipment and the time. The conversation among the workers would quickly select Sue to make up the missed operation.

For example, each column in Figure 3 represents a successive welding robot in an assembly line. The rows in each column identify operations that the robot is able to execute. When a operation fails on one robot, it can be made up on the same car body by a robot further down the line, and on subsequent bodies by robots in either direction. Figure 4 shows how the MAS analyzes status information from the production line and reassigns operations as needed.

Flavors Technology proposes to develop the technology for a Manufacturing Agility Server, based on autonomous software agents, that enables a set of functionally redundant devices to reassign operations normally executed by a device that has become unavailable, in real time.

Manufacturing identifies the initial application domain.Agility specifies the functionality that the MAS provides: the ability to respond automatically to unexpected changes in the environment.Server describes the overall architecture. The MAS attaches to a network of controllers serving a manufacturing cell or line, recommending alternative devices for failed operations. |

|

Why Agents? [Return to Top of Page]

The MAS is based on agent technology because agents can generate rich system behavior that is less brittle than centralized code when the system is modified and is adapted to modern computing technology.

A software agent is an object with its own thread of control (an "active object") and its own initiative. It differs from other software structures (such as subroutines or conventional objects) because it does not need to be invoked, but takes action autonomously on the basis of its local view of the world. As a result, the behaviors of the overall system increase exponentially with the number of agents. Ten agents, each 100 lines of code in length and each capable of five different behaviors, constitute a system with 5 billion possible behaviors, overwhelmingly larger than most systems consisting of 1000 lines of code. The individual autonomy based on local behavior is exactly what is needed to overcome the rigidity of conventional controls for manufacturing lines.

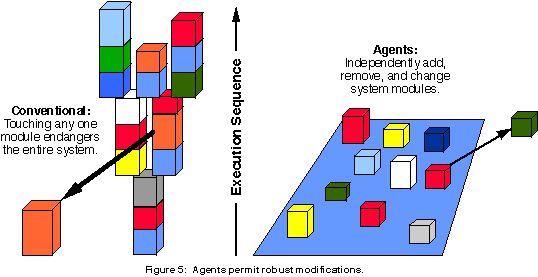

Agent-based systems are also less brittle than conventional ones. MAS-like functionality could be provided without agents, using a monolithic rule-based or constraint-propagation approach, but then any changes in the physical configuration would require expensive modification of the control software. The risk of introducing errors in such modifications often means that the risk of reconfiguration is too great and the economic benefits cannot be realized. With MAS, when physical devices are added or removed, no reprogramming is needed. Instead, the corresponding changes are simply made to the population of agents in the MAS. Figure 5 illustrates the robustness of the agent approach, supporting system expansion and modification.

|

Flavors Technology,

Inc. |