|

Flavors Technology Incorporated |

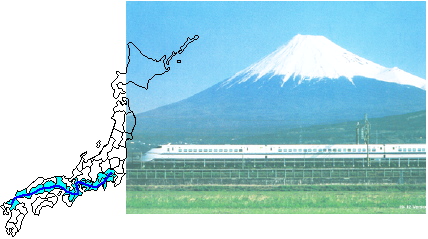

Central JR Shinkhansen Simulator

|

Introduction

Takashi Kawakami, manager of information system development at

Central Japan Railway Company, was pondering in 1992. It was time

to plan the next generation of their COMTRAC (COMputer aided TRAffic

Control) system, the Shinkansen (Bullet Train) control and monitoring

system.

The Tokaido and Sanyou Shinkansen Lines between Tokyo and Hakata,

1,100 km (700 mi) long, are the busiest among all the Shinkansen

lines. On averrage, the lines carry 300,000 passengers everyday,

with a peak of 1 million per day, on about 1,000 trains at a speed

of 270 km/h (170 mph). This is something like 4,000 Boeing 747's

flying back and forth between San Francisco and Los Angeles. They

must increase the train frequency, keep the minuscule operation

error of 15 to 30 seconds, while maintaining their safety legend--no

passenger accidents in the thirty year history.

Central JR was wondering to what extent they could improve the

next generation system. They were also wondering how they would

test the new system and train the dispatchers. On the other hand,

they had had enough of long delivery and high cost of computer

systems and application software. These information systems, including

minor modifications, had always been contracted to a few mainframe

computer manufacturers. These systems had become black boxes for

the user, Central JR.

A new agent-based and complexity-based parallel computer and software

concept was introduced. Kawakami of Central JR quickly recognized

that his staff, without programming experience, could build information

systems on their own using the PIM and Paracell. They could test

what-if simulations on the do-it-yourself systems and evolve the

systems by themselves. These systems simulate operations as realistically

as the real complex world would be, giving proof to the plans,

developments, designs and schedules of the railway system.

Railroad system simulators are a natural application for the products.

With any conventional programming scheme and computer it would

have taken as much time and cost to build a simulator as a real

control system. Paracell, the programming language, and the PIM,

the parallel execution machine, made it possible to build such

a simulator at less than one third of the cost originally estimated.

Central JR has proved all of three major advantages of the PIM/Paracell

system with building the simulator. First, the simulation is real

time and the central control computer cannot identify which is

the real train operation or the simulator. Yaskawa Electric Corporation,

the supplier, did no application program coding at all. Application

programming was accomplished by domain experts - not programmers

- from Central JR. Third, the simulator easily scaled up from

the first small scale trials, ending up as a large scale system

to cover the whole distance of 1,100 km (700 mi).

Satisfied with the success of the simulator for their development,

Central JR is going forward to include the PIM/Paracell simulator

on on a much larger scale for the next generation Shinkansen Operation

Control and Monitoring (COMTRAC) system.

The Tokaido and Sanyo Shinkansen (Bullet Train) System

The Shinkansen operation started in 1964, over three decades ago.

Operations began running one Hikari super express and one Kodama

super express per hour. The Hikari and Kodama lines had the same

performance of 210 km/h (130 mph), but Hikari stopped at only

major stations and Kodama stopped at every station between Tokyo

and Osaka, covering 500 km (300 mi). Today, there are three classes

of bullet trains: Nozomi, Hikari and Kodama are running along

the Tokaido and Sanyo lines between Tokyo and Hakata, a distance

of 1,100 km (700 mi).

Nozomi has the fastest operation, running at a speed of 270 km/h

(170 mph). During peak hours, trains arrive and depart the Tokyo

station every three and a half minutes. The train frequency today

is one Nozomi, seven Hikaris and three Kodamas per hour compared

with just one Hikari and one Kodama 32 years ago. The JR company

is planning to add another Nozomi soon and then one more per hour.

Despite this heavy traffic, the system operates right on schedule

with a minuscule error of 15 to 30 seconds, most of the time.

There has not been a single passenger accident in the 32 years

history of Shinkansen.

Developing schedules involves months of work for quite a few railway

experts. They know what affects the train operations: available

trains, maintenance cycle, available drivers, different train

performance, stations, distance, signals, track switches, curves,

slopes, tunnels, bridges, and so on. Even extra trains must be

scheduled in advance, yet there is no way to run ad hoc trains.

Can they apply a big change all at once? No, when they started

the Nozomi 270 km/h super express, only four of those per day

could run only early morning and late at night. It took several

months before hourly operation of the Nozomi began.

There is a bottleneck near the Tokyo terminal station, the busiest

station. Since the Tokyo station has no hind tracks, arriving

trains and departing trains must cross over the main tracks. To

make things worse, the train yard is located before the terminal

station, not in hinterland, so that deadhead trains must travel

for a while on the busy main tracks. To reduce this problem and

increase the train frequency, Central JR is planning to build

another terminal station, Shinagawa, a few miles before the Tokyo

station. They must check the effects of the new station before

actual construction occurs.

On January 17, 1995, a big earthquake destroyed the Kobe Shinkansen

station and nearby tracks a few minutes before the train operation

of the day began. If it were after, a couple of trains with more

than 1,000 passengers could have crashed down to the ground. Japan

Railway barely escaped the death of their safety legend. The train

operation in this area had to be shut down for 100 days. JR was

losing US$15 million every day during that time.

The big earthquake in Kobe convinced Japan Railway to build the

second control center in Osaka in addition to today's sole control

center in Tokyo. The two centers will work as a back-up system.

When one center is on-line, the other is used to train the operation

center dispatchers. They need a simulator system to work with

the back-up system for dispatcher training.

The 300 km/h (190 mph) trains are already in test and will soon

be put into operation. They are planning even faster trains (200+

mph). New trains with different performance will make the already

complex system and its scheduling more complicated. There might

be undesirable emergent, chaotic, behavior. They need a simulator

system to check this.

If, for example, snow causes a delay, what happens? The whole

system goes out of control. Of course, there is no real danger

to passengers. The problem is that nobody knows the new schedules

even after the cause of the delay is removed. The train drivers

know only the original schedules instead of the new feasible ones.

Thus, every driver tries to catch up with the original schedules.

Soon, several trains are stuck following a train that stops at

a station. As soon as the leading train leaves the station, all

of the following trains start at once causing a peak power demand

to the power substation. They want to know when the flock of trains

hits the busiest Tokyo station. They want to model revised, seemingly

feasible schedules on a simulator system that performs in faster-than-real-time

mode.

Central JR sought to improve these situations to increase the

train frequency and to make the schedules more flexible. In addition,

they had several ideas for improved service. However, prior to

designing and implementing an eintirely new system, they have

to test the ideas. But, how? They required a simulator at a reasonable

cost that provided quick turnaround time, and the ability to experiment

with different scenarios easily. Conventional simulators are either

too simple to predict system behavior or too expensive and slow

to be practical.

Building a Simulator for the Shinkansen System

The Shinkansen tracks are segmented into1.6 km (1 mi) lengths

between stations. Lengths in stations and their neighborhood are

much shorter. The total number of track segments far exceeds 1,500

since the eastbound and westbound tracks alone are about 1,100

km (700 mi) each. Each track segment is the basic unit of control

for the train traffic and includes several relay logic elements.

Track segments are locally interlocked and generate signals for

the following segments. Some of the relay logic signals are sent

to the central control system every three seconds.

The central control system sends traffic control signals including

speed limit information and route control commands, i.e., track

switching command, based on the train schedules and tracking data.

At peak hours there may be 130 or more trains on the tracks, and

the shortest period between trains is three and a half minutes.

The number for the day is about 1,000 trains.

The Shinkansen simulator developed includes about 1,000 train

agents, 130 or more of which may be on the track at a time, and

2,000 track segment agents. These agents work in parallel. Simulating

this system with a conventional programming scheme and computer

would require a very large effort and a long time in systems design,

flowcharting, coding and debugging; the resulting simulation would

be brittle. In addition, it would be hard to divide the task among

many people and nearly impossible to complete it in a short period

of time.

The programming and execution scheme of the PIM/Paracell system

simulates teamwork with a bulletin board and a clock. The team

members are to get data only from the bulletin board and to post

results on the same board. They don't need to have time-consuming

meetings. The clock frees them from directly acknowledging their

communication with each other. Adding members does not increase

overhead. Each can concentrate on his own task, yet a concerted

job can be achieved through the bulletin board and the clock.

This programming and execution scheme of the Paracell/PIM system

mapped perfectly to the desired implementation. Programming individual

small computing cells, or agents, that are to run in parallel

and in synchronization allows for train and track agents to be

quickly implemented and scaled up as needed. The concept of communicating

between agents only through the common global memory supports

the need to have a single coherent image of the system status

for running the simulation. This model fits the structure of the

Shinkansen system very well.

The actual simulator system consists of nine Macintosh computers,

each housing 1,000 PIM cells. Communication between systems is

via Ethernet. One of the units works as the central machine and

eight others simulate the 39 stations and yards that make up the

entire Shinkansen system. The application program was coded by

JR engineers using Paracell, a rule-base near-natural declarative

language. They did not necessarily have programming experience.

Rather, they had knowledge about the problem they were trying

to solve, and ideas about how to solve them. The simulator is

their product, not the supplier's, and they have a strong motivation

to improve the product further.

Simulator for the Next Generation Shinkansen System

Central JR has proved all three major advantages of the PIM/Paracell

system by building the simulator. First, the simulation is real

time and the central control computer cannot identify which is

the real train operation or the simulator. When they want prediction

of train operations, the simulator can run even faster-than-real-time.

Second, application programming was accomplished by Central JR

people without programming experience. The number of lines of

code in a conventional programming language would likely have

been ten times more than the actual code in Paracell. Third, the

simulator ended up as a large scale system to cover the whole

distance of 1,100 km (700 mi). It was a simple linear effort scaling

up from the first small rial for a few miles near the Tokyo station

to a full-scale operational simulation.

Satisfied with the success of the simulator on the Mac-PIM, Japan

Railway decided to include a simulator subsystem in their next

generation Tokaido and Sanyou Shinkansen Operation Control and

Monitoring System. It will be up and running by 1998. The simulator

subsystem will be used for testing fault-tolerant central control

computers. In addition, it will be used to train the dispatchers

for both normal and emergency operations. Finally, it will test

be used to test many what-ifs conditions as a means of integrating

new technologies, equipment, and concepts into the Shinkhansen

operations. For this next phase, a PIM system based on the PowerPC

and VME technology will provide over 20,000 PIM cells for better

reliability and more than double the capacity fo the original

PIM-based COMTRAC system. With this capacity, they will be able

to expand the scope of simulation to inlcude such areas as power

supply and demand between trains and substations.

Conclusion

Railroads are complex. Yet the PIM/Paracell system has proven

capable of simulating the Shinkansen. This technology can describe,

simulate, and find solutions to many complex problems.

|

|

Flavors Technology,

Inc.

Sunrise Labs

5 Dartmouth Drive

Auburn, NH 03032 USA

Internet: info@flavors.com

Telephone: 603-644-4500 / Fax: 603-622-9797 |