| Flavors Technology Incorporated |

PIM/Paracell Application Notes |

|

The Manufacturing Agility Server (MAS) project has developed a tool for use in concert with a welding reassignment engine known as Dynamic Load Balancing (DLB). Called the CycleAnalyzer™, this product connects seamlessly to existing control networks to monitor traffic between devices on the network. Using CycleAnalyzer, control engineers and plant floor personnel are able to collect accurate information on an event-by-event basis to better understand the dynamics of their control systems.

To better understand the applicability and functionality of CycleAnalyzer, consider the initial application of the product.

Using CycleAnalyzer to Detect a Low Productivity Robot

When an automotive welding line is being designed and commissioned, programs are often developed to meet specified cycle times on an individual device basis. Only passing attention is paid to the cumulative effect of the individual devices on the throughput of the entire line. This practice can leave significant room for improving the performance of the overall line by reassigning operations from a heavily burdened device to one with spare cycle time.

In its initial application, MAS CycleAnalyzer collects real-time data from an automotive robotic welding line as the first step in determining opportunities for reassignment. All traffic between the robot controller and the weld controller can be monitored and captured so that so that the line manager can have actual cycle-time data. In addition to providing information on the overall cycle time of a device, CycleAnalyzer collects information on each operation the robot performs; move, initiate weld, complete, squeeze, release, and so on.

The data collected by the CycleAnalyzer is made available to DLB. Based on this data, DLB can make reassignment recommendations that directly affect the throughput of the line.

CycleAnalyzer in Action

Although initially developed for use on robotic assembly lines, the CycleAnalyzer is a valuable tool for any control system implementation where engineers seek detailed information on network and device activity.

Systems developers can use the product to develop a performance record for a control system "as shipped." Once this data is collected, it can be exploited further by feeding the information back to simulation platforms so that first passes of future simulations can be more accurate. The CycleAnalyzer can be applied to a control network to accurately monitor and record traffic between controllers and plant floor I/O. This capability is valuable in troubleshooting a line, recognizing opportunities to increase throughput, or to benchmark performance between parallel lines.

CycleAnalyzer Configurations

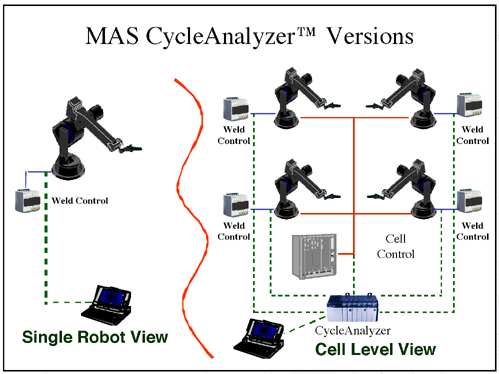

The CycleAnalyzer can be connected to DeviceNet™ or Remote I/O™ networks, and is available in two configurations. For monitoring control traffic between a single controller and a single device, the CycleAnalyzer connects to the network via a PCMCIA card and a laptop computer. To perform analysis at the cell level, CycleAnalyzer connects to the devices in a cell and to the cell controller via a stand-alone network interface box and laptop computer. Both configurations are easily connected to existing control networks, and feature mobility, minimizing the investment required to gain benefits from the product throughout the plant.

CycleAnalyzer User Interface

Keeping the human/machine interface both familiar and informative

has been a key component in the development of CycleAnalyzer.

Collected data is displayed in real time via a logic analyzer-like

user interface. The operator has the flexibility to expand the

display time scale, scroll through the data window, define the

organization and placement of the data in the display, and so

on. In addition to displaying data in real-time, collected data

can be saved in an Excel-compatible text file for further analysis

with third party applications or for use with MAS Dynamic Load

Balancing.

Background

The Manufacturing Agility Server project is a National Institute for Science and Technology (NIST) Advanced Technology Program (ATP) project funded under the Motor Vehicle Manufacturing Technology (MVMT) focused program. Flavors Technology is the prime contractor on the project, which includes team members from the Industrial Technology Institute, General Motors, Rockwell/Allen Bradley, Lamb Technicon, and the Auto Body Consortium.

The main thrust of the MAS project is to develop a real-time

reassignment technology to dynamically reassign failed operations

on a production line that is made up of devices with similar capabilities.

For example, on an automotive welding respot line, many of the

robots making up the line have overlapping capabilities. In the

event of a robot failure, the MAS would reassign that robot's

operations to other capable robots, thus enabling production to

continue while repairs are made to the failed device.

|

Flavors Technology,

Inc. |